Welcome! Use the navigation to the left to view documents.

Cautions, Notices, and Important are elements designed to prevent hazards, however, not all hazards can be foreseen. This information is placed at strategic locations within the service manual.

Caution: is used for the technician to take necessary action or not to take a prohibited action. Cautions are used to help prevent bodily injury to the technician or to the owner if the motorcycle was improperly repaired.

Notice: is used to call special attention to a necessary action or to a prohibited action. Notices are used to prevent damage to the motorcycle or prevent unnecessary repairs.

Important: is used to provide additional information or to clarify a procedure.

This symbol is located in various locations on the motorcycle to inform you that exposure to high voltage can cause shock, burns and even death.

The high voltage components on the motorcycle should be serviced by technicians with special training.

High voltage cable or wiring has an orange covering. Do not probe, tamper with, cut, or modify high voltage cable or wiring.

This manual covers the following motorcycle:

Zero FX Stealthfighter

One module power pack

• Z-Force® Li-Ion intelligent modular

• 27 hp (20 kW) Motor

• Spoke Wheels

Two module power pack

• Z-Force® Li-Ion intelligent modular

• 44 hp (33 kW) Motor

• Spoke Wheels

Version 1

Caution: Brake fluid may irritate eyes and skin. In case of contact, take the following actions:

• Eye Contact-rinse thoroughly with water

• Skin Contact-wash with soap and water

• If Ingested-contact a physician immediately

Version 1

Caution: Approved safety glasses and gloves should be worn when performing this procedure to reduce the chance of personal injury.

Version 1

Caution: Test ride the motorcycle under safe conditions. Do not attempt any maneuvers that could jeopardize the motorcycles control. Failure to adhere to these precautions could lead to serious personal injury and motorcycle damage.

Version 1

Notice: Avoid spilling brake fluid onto painted or other surfaces, electrical connections, wiring, or cables. Brake fluid will damage painted or other surfaces and cause corrosion to electrical components. If any brake fluid comes in contact with painted surfaces, immediately flush the area with water. If any brake fluid comes in contact with electrical connections, wiring, or cables, use a clean shop cloth to wipe away the fluid.

Version 1

Notice: Replacement fasteners must be the correct part number for that application. Use the correct fastener in the correct location. Fasteners requiring the use of thread-locking compound are specified in the repair procedure; refer to the product manufacture for proper usage. Always use new lock nuts, lock washers and cotter pins. Do not use paints, lubricants, or corrosion inhibitors on fasteners or fastener contact surfaces unless specified in the procedure. Coatings affect fastener torque and joint clamping force and may damage the fastener

Version 1

Caution: Always perform the High Voltage Disabling procedure prior to servicing any High Voltage component or connection. Proper procedures must be followed.

Failure to follow the procedures may result in serious injury or death.

• Always verify that the high voltage has been disabled before working on or around high voltage components, wires, cables, or harnesses.

• Remove all metal objects such as rings and watches.

• Always tighten the high voltage terminal fasteners to the specified torque. Insufficient or excessive torque will cause malfunctions or damage.

• After finishing work on the high voltage system and before turning the key ON.

• Verify high voltage system integrity and that all connectors and covers are installed.

• Verify that all tools or loose components have been removed.

Caution: Exposure to high voltage can cause shock, burns, and even death. The high voltage components on the motorcycle should only be serviced by technicians familiar with the circuit/system operation. Refer to System Description and Operation.

High voltage components are identified by labels. Do not remove, open, take apart, or modify these components. High voltage cable or wiring has orange covering. Do not probe, tamper with, cut, or modify high voltage cable or wiring.

Version 1

Although unpacking the Zero motorcycle can be done by a single person, it is recommended to have a second person to help lift and remove your motorcycle from the crate base.

Outer Box Cover

• Cut and remove the two outer box retention straps.

• Unscrew stabilizer bar bolts, one on each side of outer box.

• Open box top and remove inner cardboard end reinforcement sleeves.

• Unscrew stabilizer bar from handlebar riser and remove.

• Unscrew lower crate cover retaining screws and washers.

• Lift or cut outer box away from motorcycle.

Inner Assembly

• Carefully remove plastic cover from motorcycle.

• Locate small parts box below motorcycle and put to the side. (This box contains important documentation, owner’s manual, keys.

• Remove power pack retaining frame rail.

• Remove power pack.

• Remove the tie down straps from crate base.

• Carefully lift rear portion of the motorcycle over the swingarm standoff and off crate base.

• Carefully lift front wheel out of crate base.

• Deploy kickstand (if equipped), lean motorcycle and inspect in accordance with delivery inspection sheet.

Recycling

The Zero Motorcycles shipping crate and packaging materials were designed to be completely recycled. Please cut down and recycle all cardboard, plastic, and metal materials in appropriate receptacles.

The tie down straps that accompanied your motorcycle can be reused as regular tie down straps for transporting your motorcycle.

Version 1

|

Zero Motorcycles FX Pre-Delivery Inspection

Motorcycle Serial/VIN number:________________________________

Power Pack number:______________________ Date:___________

Technician Section After Uncrating:

|

|

|

Initial:

|

Operation:

|

|

|

Verify front axle is fully inserted, and axle pinch bolts are at specified torque.

|

|

|

Verify that front brake caliper is centered over rotor and all mounting hardware is at specified torque.

|

|

|

Verify front wheel for free operation, verify that wheel is true.

|

|

|

Verify exterior lighting is working correctly.

|

|

|

Verify the front and rear tire pressure is correct.

|

|

|

Verify the headset/steering adjustment and that all fork bolts are at specified torque.

|

|

|

Verify that the wiring connector in the instrument cluster is fully inserted and locked.

|

|

|

Verify the wiring connections on the controller and the key switch plug are fully inserted and locked.

|

|

|

Verify comfortable bar angle and check all stem/upper clamp bolts are at specified torque.

|

|

|

Verify the throttle, brake lever and motor stop switch adjustment angle and at specified torque.

|

|

|

Verify smooth throttle operation.

|

|

|

Verify that all plastics are securely fastened and all rivnuts are secure in the frame.

|

|

|

Verify that the seat bolts are at specified torque.

|

|

|

Verify that rear axle is fully inserted and end caps/pinch bolts are at specified torque.

|

|

|

Verify that rear brake caliper is centered over rotor and all mounting hardware is at specified torque.

|

|

|

Verify rear wheel for free operation, verify that wheel is true.

|

|

|

Verify that the belt tension is correct.

|

|

|

Verify main pivot bolts are at specified torque.

|

|

|

Verify audible click from solenoid when powered on.

|

|

|

Verify that battery gauge and power on LED are functional.

|

|

Road Test:

Caution: Before performing the Road Test, Refer to Road Testing Procedure.

|

|

|

|

Verify that front and rear brakes operate properly.

|

|

|

Verify throttle operation.

|

|

|

Verify smooth suspension operation and is correctly adjusted for the owners requirements.

|

|

|

Verify that the belt tension is correct after test ride.

|

|

Technician Signature:

|

|

|

Owners Section:

|

|

|

Initial:

|

Operation:

|

|

|

The technician has explained all safety warning labels.

|

|

|

I have received an owner's manual and supporting documents.

|

|

|

I understand the warranty as it has been explained to me.

|

|

|

I recognize that this is a high performance electric vehicle and requires special skills.

|

|

|

I accept that additional equipment is required to operate this motorcycle safely.

|

|

|

I will return the warranty registration card within the allotted time period.

|

|

|

I will never carry a passenger on a Zero FX motorcycle; it is designed for an operator only.

|

|

|

Know the limits of yourself and the machine on and off road.

|

|

|

I will never use alcohol or drugs while operating a Zero.

|

|

|

I will not allow a guest to operate a Zero without proper instruction.

|

|

|

I know to use the motor stop switch on the handlebar for emergency motor cut-off.

|

|

|

The technician who prepared this bike has instructed me

on the operation, maintenance, safety features, and warranty policy,

all of which I understand. I am also satisfied with the pre-delivery

set-up and inspection of my vehicle. I acknowledge that I have read all

the safety warnings and information on the product warning labels. I

understand the importance of reading the owners manual and supporting

documents completely and thoroughly. I was offered by my Certified

Service Center (CSC) to have the vehicle delivered at my expense to an

appropriate location for familiarization and self practice before I

operate it on my own.

|

|

Owners Signature:

|

|

Version 1

This manual covers the following motorcycles:

• Zero FX Stealth Fighter

-Belt Drive

-Street Tires

-Integrated Charger

-Lights

-Regenerative Braking

Identification Numbers

Loading image...

Legend

1. Identification Number

VIN Break Down

Loading image...

Location of Important Labels

Loading image...

Legend

1. VIN label (European Union) - certification label

2. VIN label (North America) - certification label shown

3. VECI (Vehicle Emission Control Information) label

Anti-Tamper Control Label (Europe Only)

Loading image...

Version 1

Tools and Equipment

Use only Zero specified tools when servicing the motorcycle. The motorcycle contains a mix of metric and standard fasteners. Use of the incorrect tool or fastener may damage the motorcycle.

All dealers should have the following:

Special Tools:

• PN 85-05665 Controller Discharge Tool

Basic Tools:

• Gloves

• Safety glasses

• Spring loaded center punch

• 2.5mm, 3mm, 4mm, 5mm, 6mm, 8mm and 10mm T, L, and socket hex wrenches

• 7 mm L Allen wrench

• T25 Torx driver or socket bit

• Zip tie pulling/cutting gun

• 7mm, 8mm, 10mm, 13mm, 14mm, 15mm, 17mm, 21mm combination wrench

• Gear puller

• Rubber dead blow hammer

• Punch

• Flat and rat tail file

• Heavy duty 420 chain breaker

• Phillips and Flat head screw drivers

• 1/4" drive 1", 2”, and 3” socket extension

• 3/8" drive 1", 2", and 3" socket extension

• Needle nose pliers

• Adjustable pin spanner wrench

• 1/4" and 3/8” drive socket wrench

• Bicycle type headset press and removal tool

• Belt tension tool

• External snap ring pliers

• 7mm, 8mm, 10mm, 13mm, 1/4" and 3/8” drive socket

• 27mm socket

• Motorcycle head bearing press and removal tool

Equipment:

• Wheel truing stand

• Tire levers and or a tire changing machine

• Motorcycle stand/lift

Version 1

|

Description

|

ZF2.8

|

ZF5.7

|

|

Motor

|

||

|

Max torque

|

70 ft-lb (95 Nm)

|

70 ft-lb (95 Nm)

|

|

Max power

|

27 hp (20 kW) @ 3,700 RPM

|

44 hp (33 kW) @ 3,700 RPM

|

|

Type

|

Z-Force® 75-7 passively air-cooled, high efficiency, radial flux, permanent high-temp magnet, brushless motor

|

Z-Force® 75-7 passively air-cooled, high efficiency, radial flux, permanent high-temp magnet, brushless motor

|

|

Controller

|

High efficiency, 420 amp, 3-phase brushless controller with regenerative deceleration

|

High efficiency, 420 amp, 3-phase brushless controller with regenerative deceleration

|

|

Power System

|

||

|

Est. pack life to 80% (city)

|

79,000 miles (127,000 km)

|

158,000 miles (254,000 km)

|

|

Power pack

|

Z-Force® Li-Ion intelligent modular

|

Z-Force® Li-Ion intelligent modular

|

|

Max capacity

|

2.8 kWh

|

5.7 kWh

|

|

Nominal capacity

|

2.5 kWh

|

5.0 kWh

|

|

Charger type

|

650 W, integrated

|

650 W, integrated

|

|

Charge time (standard)

|

4.1 hours (100% charged) / 3.7 hours (95% charged)

|

7.8 hours (100% charged) / 7.4 hours (95% charged)

|

|

CHAdeMO charge time (accessory)

|

1.5 hours (100% charged) / 1 hour (95% charged)

|

1.5 hours (100% charged) / 1 hour (95% charged)

|

|

Quick 2x charger time (accessory)

|

1.9 hours (100% charged) / 1.4 hours (95% charged)

|

3.3 hours (100% charged) / 2.8 hours (95% charged)

|

|

Drivetrain

|

||

|

Transmission

|

Clutchless direct drive

|

Clutchless direct drive

|

|

Final drive

|

132T / 25T, Poly Chain® GT® Carbon™ belt

|

132T / 25T, Poly Chain® GT® Carbon™ belt

|

|

Chassis / Suspension / Brakes

|

||

|

Front suspension

|

43 mm inverted, aluminum slider forks with adjustable compression and rebound damping

|

43 mm inverted, aluminum slider forks with adjustable compression and rebound damping

|

|

Rear suspension

|

Piggy-back reservoir shock with adjustable spring preload, compression and rebound damping

|

Piggy-back reservoir shock with adjustable spring preload, compression and rebound damping

|

|

Front suspension travel

|

9.05 in (230 mm)

|

9.05 in (230 mm)

|

|

Rear suspension travel

|

8.94 in (227 mm)

|

8.94 in (227 mm)

|

|

Front brakes

|

Nissin 2 piston hydraulic, 240x4.5 mm disc

|

Nissin 2 piston hydraulic, 313x4 mm disc

|

|

Rear brakes

|

J-Juan 1 piston hydraulic, 240x4.5 mm disc

|

J-Juan 1 piston hydraulic, 240x4.5 mm disc

|

|

Front tire

|

3.00-21

|

3.00-21

|

|

Rear tire

|

4.10-18

|

4.10-18

|

|

Front wheel

|

1.60x21

|

1.60x21

|

|

Rear wheel

|

2.15x18

|

2.15x18

|

|

Dimensions

|

||

|

Wheel base

|

56.6 in (1,438 mm)

|

56.6 in (1,438 mm)

|

|

Seat height

|

34.7 in (881 mm)

|

34.7 in (881 mm)

|

|

Rake (1/3 suspension sag)

|

26.3 °

|

26.3 °

|

|

Trail (1/3 suspension sag)

|

4.5 in (114 mm)

|

4.5 in (114 mm)

|

|

Weight

|

||

|

Frame

|

19.5 lb (8.8 kg)

|

19.5 lb (8.8 kg)

|

|

Curb weight

|

238 lb (108 kg)

|

280 lb (127 kg)

|

|

Carrying capacity

|

382 lb (173 kg)

|

340 lb (154 kg)

|

Version 1

Where time and mileage are listed, follow the interval that occurs first.

Note: From 37,000 km (24,000 miles) or 36 months, repeat the maintenance intervals starting from 13,000 km (8,000 miles) or 12 months.

|

No. |

ITEM |

ROUTINE |

EVERY RIDE |

INITIAL |

TIME INTERVALS |

||||

|

1,000 km (600 mi) or 1 month |

7,000 km (4,000 mi) or 6 months |

13,000 km (8,000 mi) or 12 months |

19,000 km (12,000 mi) or 18 months |

25,000 km (16,000 mi) or 24 months |

31,000 km (20,000 mi) or 30 months |

||||

|

1 |

Front Brake | • Check operation, and for fluid leakage. • Replace brake pads if necessary. |

● |

● |

● |

● |

● |

● |

● |

|

2 |

Rear Brake | • Check operation, and for fluid leakage. • Replace brake pads if necessary. |

● |

● |

● |

● |

● |

● |

● |

|

3 |

Wheels | • Check runout and for damage. Replace if necessary. |

● |

● |

● |

● |

● |

||

|

4 |

Tires | • Check tread depth and for damage. Replace if necessary. • Check air pressure. Correct if necessary. |

● |

● |

● |

● |

● |

● |

|

|

5 |

Wheel Bearings | • Check bearings for smooth operation. Replace if necessary. |

● |

● |

● |

● |

● |

||

|

6 |

Drive Chain (optional) | • Check chain slack/alignment and condition. • Adjust and lubricate chain with chain lubricant thoroughly. • Replace worn chain and sprockets. |

● |

Every 1,000 km (600 mi) and after washing the motorcycle or riding in the rain. | |||||

|

7 |

Steering Bearings | • Check bearing assembly for looseness. |

● |

● |

● |

● |

Repack |

● |

|

|

8 |

Chassis Fasteners | • Check all chassis fittings and fasteners. Correct if necessary. |

● |

● |

● |

● |

● |

||

|

9 |

Front Fork | • Check operation and for oil leakage. • Service/rebuild if necessary. |

● |

● |

● |

● |

● |

● |

|

|

10 |

Rear Shock Absorber Assembly | • Check operation and for oil leakage. Replace if necessary. |

● |

● |

● |

● |

● |

● |

|

|

11 |

Throttle Grip | • Check operation and free play. |

● |

● |

● |

● |

● |

● |

|

|

12 |

Kickstand Pivots |

• Check operation. • Apply silicon grease lightly. |

● |

● |

● |

● |

● |

||

|

13 |

Kickstand Switch | • Check operation and replace if necessary. |

● |

● |

● |

● |

● |

● |

|

|

14 |

Drive Belt |

• Check belt slack and condition. • Replace the belt every 40,000 km (25,000 mi). |

● |

||||||

|

15 |

Front Brake Lever Pivot Shaft | • Apply silicon grease (all-purpose grease) lightly. |

● |

● |

● |

● |

● |

||

Version 1

Important: Using the following steps of the vibration diagnostic process will help you to effectively narrow-down and pin-point the search for the specific source of a vibration concern and to arrive at an accurate repair.

Vibration Diagnostic Process

1. Gather specific information on the customer's vibration concern.

2. Perform the road testing steps in sequence as identified in Road Testing Procedure in order to duplicate the customer's concern and evaluate the symptoms of the concern under changing conditions. Observe what the vibration feels like and what it sounds like. Observe when the symptoms first appear, when they change, and when they cease.

3. Determine if the customer's vibration concern is truly an abnormal condition or something that is potentially an operating characteristic of the motorcycle.

4. Systematically eliminate or 'rule-out' possible motorcycle systems.

5. Focus diagnostic efforts on the remaining motorcycle system and systematically eliminate or "rule-out" possible components of that system.

6. Make a repair on the remaining component, or components, which have not been eliminated systematically, and must therefore be the cause of the vibration.

7. Verify that the customer's concern has been eliminated or at least brought to an acceptable level.

8. Again perform the road testing steps in sequence in order to verify that the vehicle did not have more than one vibration occurring.

Preliminary Visual/Physical Inspection

• Inspect for aftermarket equipment and modifications, which could affect the operation of the motorcycles rotating component systems.

• Inspect the easily accessible or visible components of the motorcycles rotating component systems for obvious damage or conditions, which could cause the symptom.

• Inspect the tire inflation pressures for the proper pressure.

Version 1

Caution: Refer to Road Test Caution in General Information.

Caution: Road test a motorcycle under safe conditions and while obeying all traffic laws. Do not attempt any maneuvers that could jeopardize the control of the motorcycle. Failure to adhere to these precautions could lead to serious personal injury and motorcycle damage.

Before the road test, ensure the following:

• The exterior lighting is working correctly.

• Tire pressure is correct.

During the road test:

• Perform the test only when traffic conditions permit.

• Operate the motorcycle in a controlled, safe manner.

• Observe all traffic regulations.

• Observe any unusual vibrations.

o When braking

o When coasting

o When accelerating

o When regen braking

• Observe any unusual sounds.

o When braking

o When coasting

o When accelerating

o When regen braking

Choose different road surfaces when test driving to verify that the condition is not related to road surfaces. Observe where the problem condition is located: Front, back or under the motorcycle. If the condition is something that is heard or felt, driving a similarly equipped motorcycle may determine if the issue is an operating characteristic of the motorcycle.

Version 1

For the purposes of these warranties, “proper use” means only the use of a motorcycle in the manner intended for a single rider with proper safety equipment as described in the Owner’s Manual on safe and dry surfaces in accordance with local regulations. “Proper use” also means charging the Power Pack after each use and storing it in a fully charged state, or recharging it every 15 days or keeping it on the charger when in storage or out of regular use.

Version 1

What Does This Limited Warranty Cover?

Zero Motorcycles Inc. ("Zero") warrants that all factory manufactured 2014 Zero S, Zero DS, Zero SR and Zero FX motorcycles are free from defects in material and workmanship during the period of this Limited Warranty.

This Limited Warranty covers parts, including the motor, motor controller, frame, swing arm, fork, rear shock, brake assemblies, wheels and electrical sub-assemblies, and approved Zero accessories installed at the time of purchase by an authorized Zero dealer.

This Limited Warranty also covers the following items, collectively referred to as "Power Packs":

• ZF2.8 Power Pack Modules on the Zero FX.

• The Z-Force® Power Tank and ZF2.8 Power Pack Modules that are purchased within 30 days of the original motorcycle in service date. Z-Force Power Tanks or ZF2.8 Power Pack Modules purchased after this 30-day period will carry the standard Zero Accessory Limited Warranty of 1 year and unlimited miles.

• ZF8.5 and ZF11.4 Z-Force® Li-Ion Power Packs on the Zero S, Zero DS and the Zero SR.

This Limited Warranty covers all components of the Power Packs that are included as a part of the Z-Force® Power Pack, including the battery, integrated battery management system, internal wiring, and internal structures.

Who Does This Limited Warranty Cover?

This Limited Warranty applies to all original owners who submit the warranty registration card within the required time period as printed on the registration card.

This Limited Warranty may only be transferred to new owners with payment of a $50 processing fee and submission of a new registration card by the new owner. Additional information regarding transferring this Limited Warranty may be found at http://www.zeromotorcycles.com/owner-resources/ or by contacting Zero at the following:

Via phone at (888) 841-8085 or +31 (0) 72 5112014 (Europe); via e-mail at support@zeromotorcycles.com, or via letter directed to:

North America

Zero Motorcycles Inc.

380 El Pueblo Road

Scotts Valley, CA 95066

USA

Europe

Zero Motorcycles Europe

Fluorietweg 12D

Alkmaar, Noord Holland 1812RR

Netherlands

(U.S. and International Patents and Trademarks Pending)

What is the Coverage Period of This Limited Warranty?

The duration of this Limited Warranty for 2014 Zero S, Zero DS, Zero SR and Zero FX motorcycle models, not including the Power Packs, is a period of 2 years from the original "in service date." The "in service date" is the date that the authorized dealer performs a pre-delivery inspection ("PDI") and delivers the motorcycle to the customer. In the event these events occur on different dates, the later date shall be the “in service date.”

The duration of this Limited Warranty for Power Packs, not including the Power Pack’s outer case, is as follows:

• 5 years or 50,000 miles, whichever occurs first, from the "in service date" for ZF2.8 Power Pack Modules on the Zero FX.

• 5 years or 50,000 miles, whichever occurs first, from the "in service date" for the Z-Force Power Tank on the Zero S, Zero DS and the Zero SR.

• 5 years or 100,000 miles, whichever occurs first, from the "in service date" for ZF8.5 and ZF11.4 Z-Force Li-Ion Power Packs on the Zero S, Zero DS and the Zero SR.

The Power Pack’s outer case is not covered under the Power Pack Limited Warranty duration terms above. Instead, the Power Pack’s outer case is covered for a period of 2 years from its "in service date."

What is Not Covered By This Limited Warranty?

Due to the battery chemistry, there is a normal, expected reduction in range/capacity that Power Packs can yield over time and usage. Depending on use and storage conditions, Power Packs will degrade during the duration of this Limited Warranty period. Zero will only repair or replace pursuant to this limited warranty a Power Pack that exhibits a nominal storage capacity reduction of greater than 20% of the published nominal capacity, as measured by an authorized Zero dealer. To check the capacity of a Power Pack, an authorized Zero dealer can perform a battery management system log data extraction, which will confirm if a reduction is within expected norms.

Further, this Limited Warranty only covers 2014 Zero S, Zero DS, Zero SR and Zero FX motorcycles or Power Packs that are operated according to "proper use" and "under normal operating conditions." For purposes of this exclusion, the following definitions apply:

• "Normal operating conditions" require routine care and maintenance of the 2014 Zero S, Zero DS, Zero SR and Zero FX motorcycles and Power Packs as described in the Owner’s Manual.

• "Proper use" means only the use of a motorcycle in the manner intended for a rider and passenger on a Zero S, Zero SR, Zero DS and Zero FX with proper safety equipment as described in the Owner’s Manual, in accordance with local regulations.

• "Proper use" also means charging the Power Pack after each use and storing it in a fully charged state, or recharging it every 30 days, or keeping it on the charger when in storage or not in regular use.

In addition, this Limited Warranty does not cover:

• The cost of parts and labor involved in any routine care and maintenance and/or the replacement of parts due to normal wear and tear, use, or deterioration, including but not limited to: tires, brake pads and rotors, fork seals, grips, foot pegs, and the seat;

• The replacement of fluids, unless their replacement is a necessary part of warranty service on a covered component;

• Wheels on off-road bikes once they have been ridden.

• Any cosmetic concerns that arise as a result of environmental conditions, owner abuse, misuse, lack of routine care and maintenance, and/or improper use;

• Parts or components damaged by use or operation under abnormal circumstances or contrary to the requirements described in the Zero Motorcycle Owner’s Manual.

• Zero motorcycles and Power Packs used for racing or other competitive events;

• Zero motorcycles and Power Packs misused or improperly operated;

• Damage, malfunctions, or performance problems caused by modifications or alterations to 2014 Zero S, Zero DS, Zero SR, and Zero FX motorcycles and/or Power Packs – including modifications or alterations performed by an authorized Zero dealer – that cause the Zero motorcycle or Power Pack to fail;

• Damage, malfunctions, or performance problems caused by aftermarket accessories installed on a Zero motorcycle or Power Pack after the "in service date,” or caused by aftermarket accessories installed by someone other than an authorized Zero dealer;

• Damage, malfunctions, or performance problems caused by the improper repair of the motorcycle, installation of any parts or accessories not sold or approved by Zero, the installation and use of any parties or accessories that alter the motorcycle’s specifications from those set by Zero, or the use of new or used parts not approved by Zero;

• Damage, malfunctions, or performance problems caused by fire, collision, accident, or improper storage;

• Damage, malfunctions, or performance problems caused by continued operation of the motorcycle after a warning light, gauge reading, or other warning indicates a mechanical or operational problem;

• Motorcycles severely damaged or declared to be a total loss by an insurer, or motorcycles substantially reassembled from or repaired with parts obtained from another used motorcycle;

• Damage, malfunctions, or performance problems caused by the failure to follow recommended maintenance requirements as set forth in the Zero Owner’s Manual; and,

• Damage, malfunctions, or performance problems caused by airborne industrial pollutants (e.g., acid rain), bird droppings, tree sap, stones, flood water, windstorms, or other similar occurrences;

Further, this Limited Warranty does not apply to Zero motorcycles or parts and accessories that are not imported or distributed by Zero.

Other Expenses: This Limited Warranty does not cover any incidental or consequential damages, including loss of value of the motorcycle, lost profits or earnings, out-of-pocket expenses for substitute transportation or lodging, expenses associated with returning the covered product to a authorized service facility or dealer, towing and/or roadside assistance expenses, expenses associated with returning the covered product back to its owner, mechanic’s travel time or communication charges, loss or damage to personal property, loss or time, or inconvenience. (Some states do not allow the exclusion or limitation of incidental or consequential damages, so this limitation or exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other rights, which vary from state to state.)

This Limited Warranty is the only express warranty made in connection with the sale of this Zero Motorcycle model. Any implied warranty, including any warranty of merchantability or warranty of fitness for a particular purpose is limited in duration to the stated period of this written warranty. (Some states do not allow limitations on how long an implied warranty lasts, so this limitation may not apply to you.)

Zero does not assume – or authorize any person to assume – any other obligation or liability on its behalf.

What Will Zero Do Under This Limited Warranty?

During the duration of this Limited Warranty, an authorized Zero dealer will repair or replace (at Zero’s discretion), without charge, any 2014 Zero S, Zero DS, Zero SR and Zero FX models, Power Packs, or parts that are covered by this Limited Warranty and found by Zero or an authorized Zero dealer to be defective in factory materials or workmanship.

How Do You Obtain Service Under This Limited Warranty?

Warranty services may be obtained by contacting a local authorized Zero dealer. Please see the dealer locator on www.zeromotorcycles.com for the nearest location.

Warranty services may also be obtained by contacting Zero via telephone at (888) 841-8085 or +31 (0) 72 5112014 (Europe), via e-mail at support@zeromotorcycles.com, or via written letter directed to the following:

North America

Zero Motorcycles Inc.

380 El Pueblo Road

Scotts Valley, CA 95066

USA

Europe

Zero Motorcycles Europe

Fluorietweg 12D

Alkmaar, Noord Holland 1812RR

Netherlands

(U.S. and International Patents and Trademarks Pending)

In any written or telephonic communication, please state the specific nature of and any circumstances leading to the problem.

What are Your Responsibilities as a Customer?

As the owner of a product covered by this Limited Warranty, it is your responsibility to read and understand the Owner’s Manual, this Limited Warranty, and all product warnings before operating your Zero motorcycle. Serious injury or death can result from improper operation or failure to observe warnings and safety instructions on any motorcycle.

Further, it is also your responsibility to:

• Perform all recommended and necessary routine care and maintenance and engage in proper use of your Zero motorcycle and Power Pack as detailed in the Owner’s Manual.

• Learn and obey all federal, state, and local laws governing the operations of a motorcycle, generally, and an electric motorcycle, specifically.

• At all times when operating a Zero motorcycle wear proper safety equipment and clothing, including but not limited to helmet, goggles, and appropriate boots.

What Other Limitations or Disclaimers Apply to this Limited Warranty?

The following additional limitations and disclaimers apply to this Limited Warranty:

• Zero Motorcycles reserves the right to change or improve the design of any Zero motorcycle, Power Pack, or any other Zero parts (collectively, "Zero products") at any time, without assuming any obligation to modify any Zero products previously manufactured or sold.

• The purchaser acknowledges that there is an inherent risk in the operation of motorcycles. This Limited Warranty does not cover – and Zero cannot assume responsibility for – any injury arising from the unsafe or improper operation of Zero products, or the user’s failure to comply with instructions, care and maintenance requirements, warnings, and safety precautions.

• The original registered owner or subsequent registered transferee as documented on the Zero motorcycle warranty registration form is responsible for conveying the Owner’s Manual and all safety warnings, instructions, and Limited Warranty if the unit is sold, loaned, or otherwise transferred to another person. Zero Motorcycles Inc. does not assume or authorize anyone to assume for them any other obligation.

Warranty Procedures:

Warranty services may be obtained by contacting a local authorized Zero dealer. Please see the dealer locator on www.zeromotorcycles.com for the nearest location.

Warranty services may also be obtained by contacting Zero via telephone at (888) 841-8085 or +31 (0) 72 5112014 (Europe), via e-mail at support@zeromotorcycles.com, Service may also be available from a local Zero Motorcycles dealer; please see the locator on www.zeromotorcycles.com for the nearest location.

In any written or telephonic communication, please state the specific nature of and any circumstances leading to the problem.

North America

Zero Motorcycles Inc.

380 El Pueblo Road

Scotts Valley, CA 95066

USA

Europe

Zero Motorcycles Europe

Fluorietweg 12D

Alkmaar, Noord Holland 1812RR

Netherlands

(U.S. and International Patents and Trademarks Pending)

Transfer of Ownership and Warranty?

When it comes time to sell your Zero motorcycle, please visit the Zero Motorcycles website and access the owner resources section to fill out the on-line transfer of ownership and warranty form. This must be performed to allow Zero Motorcycles the ability to contact the new owner in the unlikely event of a safety related issue. Use the URL address below or feel free to contact the Zero Motorcycles Customer Service department for assistance.

North America

Phone: (888) 841-8085

Monday-Friday

8am to 5pm Pacific Time

E-mail: support@zeromotorcycles.com

Europe

Phone: +31 (0) 72 5112014

E-mail: support@zeromotorcycles.com

For updates and additional information about your motorcycle, visit the owner resources section of Zero Motorcycles website:

http://www.zeromotorcycles.com/owner-resources/

Version 1

Zero Motorcycles Inc. can be contacted via the contact methods listed below. Please have available the following, as it is essential to effectively and efficiently answer your questions or resolve your concerns.

• Owner’s name and address

• Owner’s telephone number

• Vehicle identification number (VIN)

• Date of purchase

• Power Pack serial number

• Motor serial number

An owner information chart is provided in the Zero Motorcycles Owner's Manual to record this information.

North American and Canada:

Zero Motorcycles

380 El Pueblo Rd.

Scotts Valley, California 95066

USA

Phone: (888) 786-9376

Monday-Friday

8am to 5pm Pacific Time

Europe:

Zero Motorcycles BV

Fluorietweg 12D

Alkmaar, 1812 RR

NL

E-mail: service@zeromotorcycles.com

24 hours

International Contacts:

For the most up to date information, please refer to http://www.zeromotorcycles.com/contact

Version 1

|

Application

|

Specification

|

|

|

Type of Material

|

Part Number

|

|

| Axle End Cap Bolts | Threadlock | 242 |

| Axle Pinch Bolts | Threadlock | 242 |

| Brake Fluid | Fluid | DOT 4 |

| Brake Rotor Bolts | Threadlock | 242 |

| Caliper Bolts (Front) | Threadlock | 242 |

| Caliper Bolts (Rear) | Threadlock | 242 |

| Fork Bearings | Dupont™ Teflon® Service Grease | — |

| Lower Chain Guide Bolts | Anti-seize | — |

| Master Cylinder Shield Bolts | Threadlock | 242 |

| Motor Shaft | Threadlock | 680 |

| Motor Shaft Bolt | Threadlock | 271 |

| Rear Axle End Cap Bolts | Threadlock | 242 |

| Rear Brake Pedal Pivot Bolt | Threadlock | 242 |

| Shock Bolts | Anti-seize | — |

| Triple Tree Pinch Bolts | Threadlock | 242 |

Version 1

CAUTION: Under-inflation is the most

common cause of tire failure and may result in severe tire cracking,

tread separation, “blowout,” or unexpected loss of motorcycle control

causing personal injury and possible death.

The tire pressure is checked using an accurate gauge when the tires are

cold. This means that the tires have not been ridden on for 3 hours.

Always replace the valve stem cap when finished.

|

MODEL

|

FRONT

|

REAR

|

|

FX

|

200 kpa

(29 psi)

|

186 kpa

(27 psi)

|

Version 1

|

PART

|

NUMBER

|

|

Headlight Bulb

|

H3 (55 watt)

|

|

Turn Signal Light Bulb (amber)

|

RY10W (10 watt)

|

|

Brake/Tail Light Bulb

|

LED (replace entire unit)

|

|

Front Running Light Bulb

|

W3W (3 watt)

|

Version 1

Whenever there is an excessive amount of current flowing through a

circuit the fusible element will melt and create an open or incomplete

circuit. Fuses are a one-time protection device and must be replaced

each time the circuit is overloaded. Replace the fuse with one of equal

current and voltage rating. If the fuse melts repeatedly, inspect the

circuit for an overload or short.

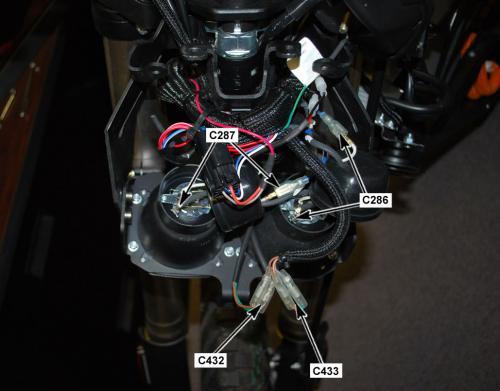

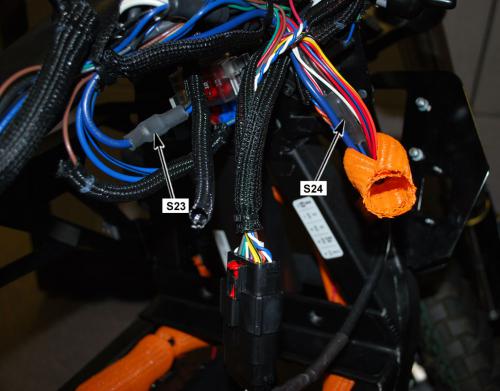

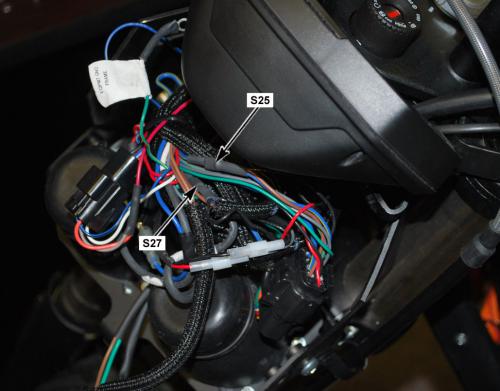

Fuse Center Location

12 Volt

The 12 volt fuse center is located in front of the front power pack, on the right side of the frame. The fuse center has a protective cover that must first be removed to gain access to the fuses. To remove the cover, squeeze the tabs together and lift off the cover (A).

|

Fuse Number

|

Amp

|

Circuits Controlled

|

|

1

|

10

|

Voltage to Splice S25

• Headlight Switch

|

|

2

|

10

|

• Accessory Power Port

• Accessory Power Connector

|

|

3

|

10

|

Voltage to Splice S27

• Horn • Turn Signal Flasher • Brake Switches

|

|

4

|

5

|

Voltage to Splice S299

• Instrument Panel • Tail Light • Main Bike Board

•Running Light 1 and 2

|

Inline Fuse:

There are 3 inline 12 volt fuses, these are inside the harness covering.

DC/DC Converter Fuse

|

Fuse Number

|

Amp

|

Circuits Controlled

|

|

C7

|

4

|

DC/DC Converter

|

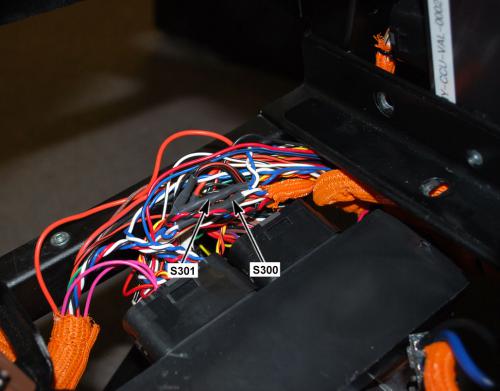

Note: Trim panel removed for clarity.

Below the front power pack inside the harness cover.

Main Bike Board (MBB) Fuse

|

Fuse Number

|

Amp

|

Circuits Controlled

|

|

C47

|

4

|

Main Bike Board (MBB)

|

Note: Trim panel removed for clarity.

Below the front power pack, across from the MBB, inside the harness cover.

Charger Control Unit (CCU) Fuse

|

Fuse Number

|

Amp

|

Circuits Controlled

|

|

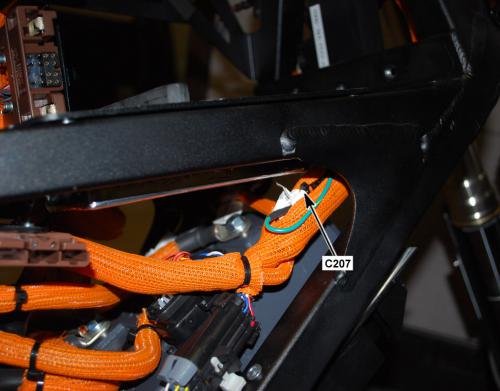

C207

|

10

|

Charger Control Unit (CCU)

|

Note: Trim panel removed for clarity.

Below the front power pack, across from the MBB, inside the harness cover.

Version 1

|

Application

|

Specification

|

|

|

Type of Material

|

Part Number

|

|

| Axle End Cap Bolts | Threadlock | 242 |

| Axle Pinch Bolts | Threadlock | 242 |

| Brake Fluid | Fluid | DOT 4 |

| Brake Rotor Bolts | Threadlock | 242 |

| Caliper Bolts (Front) | Threadlock | 242 |

| Caliper Bolts (Rear) | Threadlock | 242 |

| Fork Bearings | Dupont™ Teflon® Service Grease | — |

| Lower Chain Guide Bolts | Anti-seize | — |

| Master Cylinder Shield Bolts | Threadlock | 242 |

| Motor Shaft | Threadlock | 680 |

| Motor Shaft Bolt | Threadlock | 271 |

| Rear Axle End Cap Bolts | Threadlock | 242 |

| Rear Brake Pedal Pivot Bolt | Threadlock | 242 |

| Shock Bolts | Anti-seize | — |

| Triple Tree Pinch Bolts | Threadlock | 242 |

Version 1

CAUTION: Under-inflation is the most

common cause of tire failure and may result in severe tire cracking,

tread separation, “blowout,” or unexpected loss of motorcycle control

causing personal injury and possible death.

The tire pressure is checked using an accurate gauge when the tires are

cold. This means that the tires have not been ridden on for 3 hours.

Always replace the valve stem cap when finished.

|

MODEL

|

FRONT

|

REAR

|

|

FX

|

200 kpa

(29 psi)

|

186 kpa

(27 psi)

|

Version 1

|

PART

|

NUMBER

|

|

Headlight Bulb

|

H3 (55 watt)

|

|

Turn Signal Light Bulb (amber)

|

RY10W (10 watt)

|

|

Brake/Tail Light Bulb

|

LED (replace entire unit)

|

|

Front Running Light Bulb

|

W3W (3 watt)

|

Version 1

Whenever there is an excessive amount of current flowing through a

circuit the fusible element will melt and create an open or incomplete

circuit. Fuses are a one-time protection device and must be replaced

each time the circuit is overloaded. Replace the fuse with one of equal

current and voltage rating. If the fuse melts repeatedly, inspect the

circuit for an overload or short.

Fuse Center Location

12 Volt

The 12 volt fuse center is located in front of the front power pack, on the right side of the frame. The fuse center has a protective cover that must first be removed to gain access to the fuses. To remove the cover, squeeze the tabs together and lift off the cover (A).

|

Fuse Number

|

Amp

|

Circuits Controlled

|

|

1

|

10

|

Voltage to Splice S25

• Headlight Switch

|

|

2

|

10

|

• Accessory Power Port

• Accessory Power Connector

|

|

3

|

10

|

Voltage to Splice S27

• Horn • Turn Signal Flasher • Brake Switches

|

|

4

|

5

|

Voltage to Splice S299

• Instrument Panel • Tail Light • Main Bike Board

•Running Light 1 and 2

|

Inline Fuse:

There are 3 inline 12 volt fuses, these are inside the harness covering.

DC/DC Converter Fuse

|

Fuse Number

|

Amp

|

Circuits Controlled

|

|

C7

|

4

|

DC/DC Converter

|

Note: Trim panel removed for clarity.

Below the front power pack inside the harness cover.

Main Bike Board (MBB) Fuse

|

Fuse Number

|

Amp

|

Circuits Controlled

|

|

C47

|

4

|

Main Bike Board (MBB)

|

Note: Trim panel removed for clarity.

Below the front power pack, across from the MBB, inside the harness cover.

Charger Control Unit (CCU) Fuse

|

Fuse Number

|

Amp

|

Circuits Controlled

|

|

C207

|

10

|

Charger Control Unit (CCU)

|

Note: Trim panel removed for clarity.

Below the front power pack, across from the MBB, inside the harness cover.

Version 1

|

Application

|

Specification

|

|

|

Metric

|

English

|

|

|

Brushless Motor Controller Cable Bolt

|

11 N•m

|

8 lb ft

|

|

Brushless Motor Controller Upper Bracket Bolts

|

11 N•m

|

8 lb ft

|

|

Controller Nuts and Bolts

|

1.3 N•m

|

12 lb in

|

|

Front Fairing Bolts

|

1.3 N•m

|

12 lb in

|

|

Front Fender Bolts

|

2 N•m

|

22 lb in

|

|

Instrument Panel Nuts

|

4 N•m

|

36 lb ft

|

|

Seat Bolts

|

15 N•m

|

11 lb ft

|

Version 1

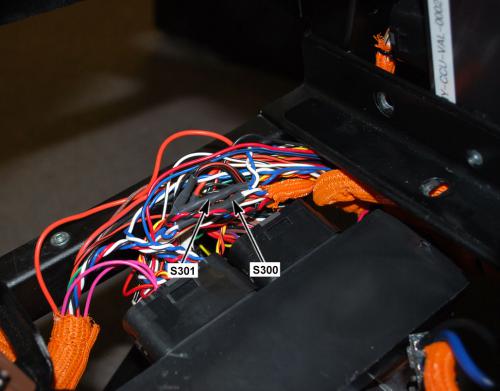

Legend

1. Rear Power Pack

2. Front Power Pack

3. Integrated Power Pack Chargers

4. Charger Control Unit (CCU)

5. Main Bike Board (MBB)

6. Brushless Motor Controller

7. DC/DC Converter

8. Brushless Motor

Version 1

Version 1

Version 1

|

SCH2515

Loading image...

|

Version 1

|

SCH2516

Loading image...

|

Version 1

|

SCH2521

Loading image...

|

Version 1

|

SCH2515

Loading image...

|

Version 1

|

SCH2516

Loading image...

|

Version 1

|

SCH2521

Loading image...

|

Version 1

|

SCH2525

Loading image...

|

Version 1

|

SCH2491

Loading image...

|

Version 1

|

SCH2524

Loading image...

|

Version 1

|

SCH2522

Loading image...

|

Version 1

|

SCH2533

Loading image...

|

Version 1

|

SCH2534

Loading image...

|

Version 1

|

SCH2528

Loading image...

|

Version 1

|

SCH2526

Loading image...

|

Version 1

|

SCH2529

Loading image...

|

Version 1

|

SCH2529

Loading image...

|

Version 1

|

C1 Main Bike Board Connector Face View |

|||

|

18007

|

|||

|

Connector Part Information |

|

||

|

Pin |

Wire Color |

Function |

|

| 1 | ORN/RED | Motor Controller Enable | |

| 2 | ORN/BLU | Motor Controller Digital Input 1 | |

| 3 | ORN/VIO | Motor Controller Digital Input 3 | |

| 4-6 | — | Not Used | |

| 7 | ORN/BLK | Power Pack Ground | |

| 8 | BRN | System ON Signal | |

| 9 | BRN/WHT | System ON Output | |

| 10 | — | Not Used | |

| 11 | YEL/BLK | Kickstand Switch Signal | |

| 12 | ORN/BLK | Kickstand Switch Ground | |

| 13 | — | Not Used | |

| 14 | WHT/BLK | Fuel Gauge 5V Reference | |

| 15 | YEL/GRN | Key ON 12V | |

| 16 | YEL | Temperature Warning Lamp Control | |

| 17 | YEL/BLK | Warning Lamp Control | |

| 18 | ORN/BRN | MBB Low Power | |

| 19 | ORN/GRY | Motor Controller Neutral | |

| 20 | ORN/RED | DC/DC Converter Enable | |

| 21 | ORN/YEL | Motor Controller Digital Input 2 | |

| 22 | BLK/WHT | Battery Throttle Enable | |

| 23 | RED | Motor Stop Switch 5V | |

| 24 | WHT | Motor Stop Switch IN | |

| 25-26 | — | Not Used | |

| 27 | RED | Kickstand Switch Signal | |

| 28 | WHT/RED | Brake Switch Input | |

| 29 | BLK | 12 Volt Ground | |

| 30 | BRN | 12 Volt Positive | |

| 31 | — | Not Used | |

| 32 | ORN/BLK | Instrument Cluster Light Ground | |

| 33 | VIO | Charge Indicator Control | |

| 34 | RED/WHT | Armed Indicator Light Control | |

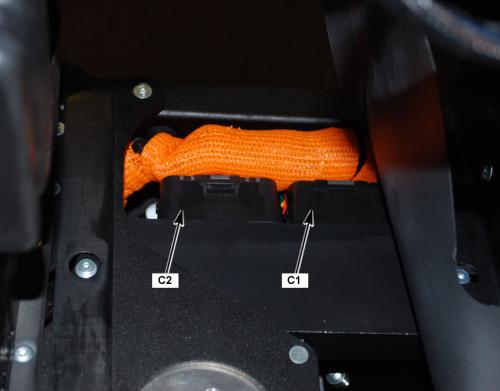

| Under the Cover, Below the Front Power Pack |

|

COM1458

Loading image...

|

Version 1

|

C2 Main Bike Board Connector Face View |

||

|

CON0765

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| 1 | ORN/BLK | Motor Controller Enable |

| 2 | YEL/RED | Motor Controller 24 Volt |

| 3 | BLK | CAN 0 Ground |

| 4 | RED | CAN 0 5 Volts |

| 5 | BLK | CAN 1 Ground |

| 6 | WHT | CAN 2 High |

| 7 | BLU | CAN 2 Low |

| 8 | BLK | CAN 2 Ground |

| 9 | RED | CAN 2 5 Volts |

| 10 | RED/ORN | Diagnostic 3 3 Volts |

| 11-12 | — | Not Used |

| 13 | PNK | Loopback Return |

| 14 | PNK | Loopback Source |

| 15 | BLU/BLK | Start Switch Input |

| 16 | — | Not Used |

| 17 | BLK | Ambient Temperature |

| 18 | ORN/GRN | On Board Charger Attached |

| 19 | ORN/BLK | On Board Charger Reference |

| 20 | WHT/BLK | On Board Charger Enable |

| 21 | BLU | CAN Low Motor Controller |

| 22 | WHT | CAN High Motor Controller |

| 23 | BLU | CAN 0 Low |

| 24 | WHT | CAN 0 High |

| 25 | BLU | CAN 1 Low |

| 26 | WHT | CAN 1 High |

| 27-28 | — | Not Used |

| 29 | RED/BLK | U-ART Tx |

| 30 | GRY/BLK | U-ART Rx |

| 31 | ORN/BLK | Diagnostic Ground |

| 32-34 | — | Not Used |

| 35 | RED | Ext Switch 5V |

| 36-37 | — | Not Used |

| 38 | WHT/BLK | Ext Charger Enable 0 |

| 39 | — | Not Used |

| 40 | WHT/BRN | Ext Charger Enable 1 |

| Under the Cover, Below the Front Power Pack |

|

COM1458

Loading image...

|

Version 1

|

C3 Data Link Connector Face View |

||

|

18502

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| 1-3 | — | Not Used |

| 4 | BLK/BLU | 12 Volt Ground |

| 5 | ORN/BLK | Diagnostic Ground |

| 6 | WHT | CAN 1 High |

| 7 | — | Not Used |

| 8 | RED/BLK | U-Art Tx |

| 9 | GRY/BLK | U-ART Rx |

| 10 | — | Not Used |

| 11 | BLK | CAN 1 Ground |

| 12 | RED/ORN | Diagnostic 3.3 Volts |

| 13 | — | Not Used |

| 14 | BLU | CAN 1 Low |

| 15-16 | — | Not Used |

| Left Side of the Frame, Between the Horn and the Front Power Pack |

|

COM1459

Loading image...

|

Version 1

|

17841

Loading image...

|

|||||

| Connector Part Information |

|

Connector Part Information |

|

||

| Pin | Wire Color | Function | Pin | Wire Color | Function |

| 1 | — | Not Used |

1 |

— |

Not Used |

| 2 | BLU | Throttle Sensor Voltage |

2 |

— |

Throttle Sensor Voltage |

| 3 | BRN | Throttle Sensor Signal |

3 |

— |

Throttle Sensor Signal |

| 4 | ORN/BLK | Ground to Brushless Motor Controller |

4 |

— |

Ground to Brushless Motor Controller |

| Right Side of the Frame, Above the Power Pack Chargers |

|

COM1460

Loading image...

|

Version 1

|

C7 DC/DC Converter Fuse Connector Face View |

||

|

con0770

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| 1 | ORN | Low Voltage (+) Input |

| 2 | ORN/BLU | Low Voltage (+) Output |

| Below the Front Power Pack, Inside the Harness Cover |

|

COM1472

Loading image...

|

Version 1

|

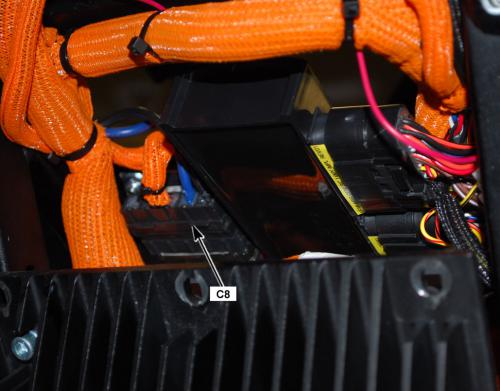

C8 DC/DC Converter Connector Face View |

||

|

18513

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| 1 | BLK | Accessory 0 Volts |

| 2 | BLU | Accessory 12 Volts |

| 3 | ORN/BLK | Negative Input Voltage |

| 4 | ORN/BLU | Positive Input Voltage |

| 5 | ORN/RED | Converter Control |

| Right Front of the Frame, Under the Front Power Pack |

|

COM1473

Loading image...

|

Version 1

|

18512

Loading image...

|

|||||||

| Connector Part Information |

|

Connector Part Information |

|

||||

| Pin | Wire Color | Function | Pin | Wire Color | Function | ||

| 1 | BLU | 5 Volts | 1 | RED | 5 Volts | ||

| 2 | BLK | Battery Negative | 2 | ORN/BLK | Battery Negative | ||

| 3 | PNK | Kickstand Switch IN Signal | 3 | YEL/BLK | Kickstand Switch IN Signal | ||

| Left Side of the Frame, Next to the Brushless Motor Controller |

|

COM1461

Loading image...

|

Version 1

|

19328

Loading image...

|

|||||

| Connector Part Information |

|

Connector Part Information |

|

||

| Pin | Wire Color | Function | Pin | Wire Color | Function |

| A | WHT | Sine Digital Input | A | BLU | Sine Digital Input |

| B | BLU | Cosine Input | B | WHT | Cosine Input |

| C | BLK | Encoder Power Supply (–) | C | BLK | Encoder Power Supply (–) |

| D | — | Not Used | D | — | Not Used |

| E | RED | Encoder Power Supply (+) | E | RED | Encoder Power Supply (+) |

| F | GRN | Shield | F | — | Shield |

| G | YEL | Motor Controller Ground | G | ORN/BLK | Motor Controller Ground |

| H | YEL | Temperature Sensor Input | H | WHT | Temperature Sensor Input |

| Right Side of the Frame, Next to the Brushless Motor Controller |

|

COM1462

Loading image...

|

Version 1

|

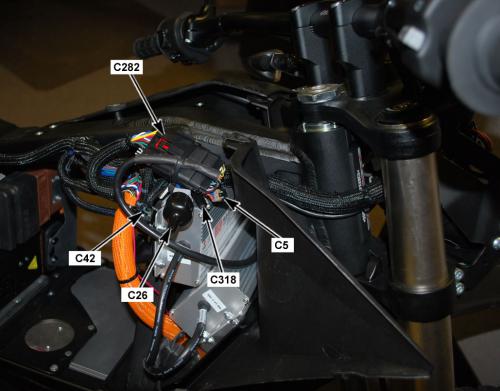

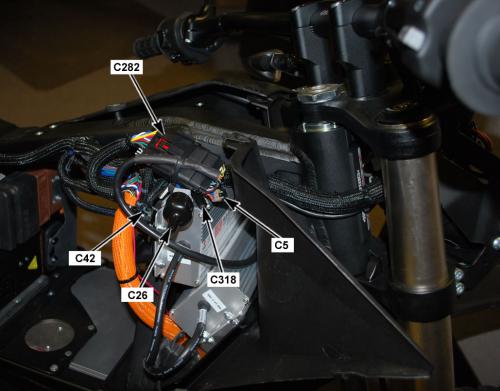

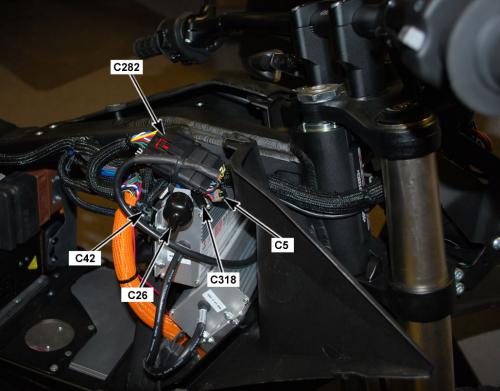

C26 Accessory Power Port Connector Face View |

||

|

CON0759

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| 1 | BLU | Fuse 2 Voltage |

| 2 | BLK | Ground, Accessory 0 V |

| Right Side of the Frame, Above the Power Pack Chargers |

|

com1460

Loading image...

|

Version 1

|

C32 Horn Connector Face View |

||

|

con0758

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

|

1 |

BLK/YEL |

Horn Ground Control |

|

C32 Horn Connector Face View |

||

|

con0758

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

|

2 |

BLU/BLK |

Horn Supply Voltage |

| Left Front Side of the Frame |

|

com1459

Loading image...

|

Version 1

|

19226

Loading image...

|

|||||

| Connector Part Information |

|

Connector Part Information |

|

||

| Pin | Wire Color | Function | Pin | Wire Color | Function |

| 1 | WHT | Left Front Turn Signal Voltage | 1 | GRN | Left Front Turn Signal Voltage |

|

19226

Loading image...

|

|||||

| Connector Part Information |

|

Connector Part Information |

|

||

| Pin | Wire Color | Function | Pin | Wire Color | Function |

| 2 | BLK | Left Front Turn Signal Ground | 2 | BLK | Left Front Turn Signal Ground |

| Under the Instrument Panel, Behind the Headlight |

|

com1484

Loading image...

|

Version 1

|

19226

Loading image...

|

|||||

| Connector Part Information |

|

Connector Part Information |

|

||

| Pin | Wire Color | Function | Pin | Wire Color | Function |

| 1 | RED | Right Front Turn Signal Voltage | 1 | GRY | Right Front Turn Signal Voltage |

|

19226

Loading image...

|

|||||

| Connector Part Information |

|

Connector Part Information |

|

||

| Pin | Wire Color | Function | Pin | Wire Color | Function |

| 2 | BLK | Right Front Turn Signal Ground | 2 | BLK | Right Front Turn Signal Ground |

| Under the Instrument Panel, Behind the Headlight |

|

com1457

Loading image...

|

Version 1

|

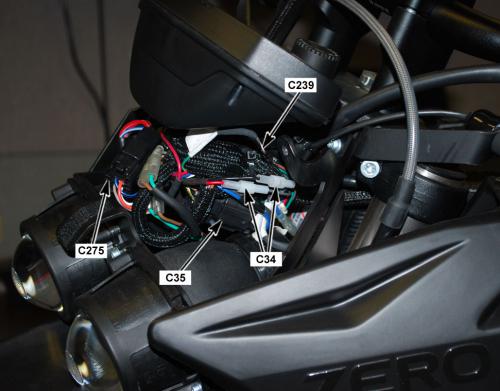

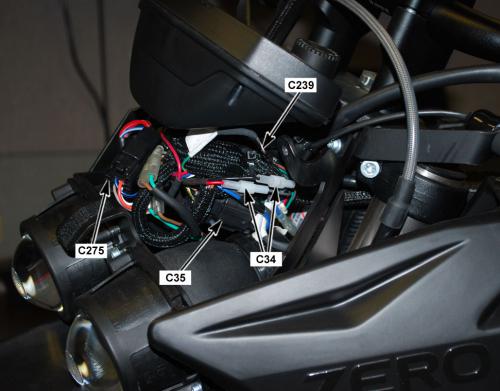

C35

Loading image...

|

|||||

| Connector Part Information |

|

Connector Part Information |

|

||

| Pin | Wire Color | Function | Pin | Wire Color | Function |

| 1 | — | Not Used | 1 | — | Not Used |

| 2 | BRN | High Beam Input (Flash to Pass) | 2 | BRN | High Beam Input (Flash to Pass) |

| 3 | RED/YEL | Headlamp Low Beam Voltage | 3 | RED/YEL | Headlamp Low Beam Voltage |

| 4 | RED/BLK | Headlamp High Beam Voltage | 4 | RED/BLK | Headlamp High Beam Voltage |

| 5 | BLU/YEL | Headlamp Switch Voltage | 5 | BLU/YEL | Headlamp Switch Voltage |

| 6 | BLK/YEL | Horn Voltage | 6 | BLK/YEL | Horn Voltage |

| 7 | BLK/WHT | Horn Switch Ground | 7 | BLK | Horn Switch Ground |

| 8 | GRY | Right Turn Signal Lamp Voltage | 8 | GRY | Right Turn Signal Lamp Voltage |

| 9 | GRY/GRN | Turn Signal | 9 | ORN | Turn Signal |

| 10 | GRN | Left Turn Signal Lamp Voltage | 10 | GRN | Left Turn Signal Lamp Voltage |

| Under the Instrument Panel, Behind the Headlight |

|

com1457

Loading image...

|

Version 1

|

19227

Loading image...

|

|||||

| Connector Part Information |

|

Connector Part Information |

|

||

| Pin | Wire Color | Function | Pin | Wire Color | Function |

| 1 | BLU/BLK | Foot Brake Switch Supply Voltage | 1 | BLK | Foot Brake Switch Supply Voltage |

| 2 | WHT/RED | Foot Brake Switch Signal | 2 | BLK | Foot Brake Switch Signal |

| On the Right Side of the Frame, Behind the Power Pack |

|

com1463

Loading image...

|

Version 1

|

19226

Loading image...

|

|||||

| Connector Part Information |

|

Connector Part Information |

|

||

| Pin | Wire Color | Function | Pin | Wire Color | Function |

| 1 | RED | Left Rear Turn Signal Voltage | 1 | GRN | Left Rear Turn Signal Voltage |

|

19226

Loading image...

|

|||||

| Connector Part Information |

|

Connector Part Information |

|

||

| Pin | Wire Color | Function | Pin | Wire Color | Function |

| 2 | BLK | Left Rear Turn Signal Ground | 2 | BLK | Left Rear Turn Signal Ground |

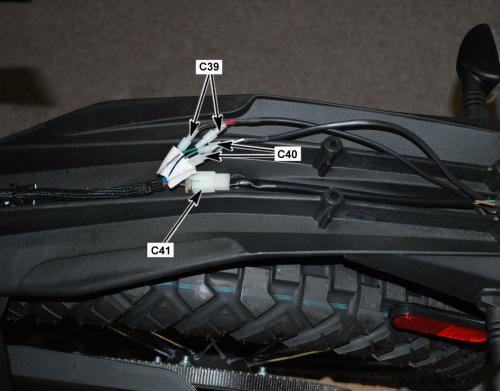

| Above the Rear Fender |

|

com1464

Loading image...

|

Version 1

|

19226

Loading image...

|

|||||

| Connector Part Information |

|

Connector Part Information |

|

||

| Pin | Wire Color | Function | Pin | Wire Color | Function |

| 1 | WHT | Right Rear Turn Signal Voltage | 1 | GRY | Right Rear Turn Signal Voltage |

|

19226

Loading image...

|

|||||

| Connector Part Information |

|

Connector Part Information |

|

||

| Pin | Wire Color | Function | Pin | Wire Color | Function |

| 2 | BLK | Right Rear Turn Signal Ground | 2 | BLK | Right Rear Turn Signal Ground |

| Above the Rear Fender |

|

com1464

Loading image...

|

Version 1

|

17856

Loading image...

|

|||||

| Connector Part Information |

|

Connector Part Information |

|

||

| Pin | Wire Color | Function | Pin | Wire Color | Function |

| 1 | WHT/RED | Tail Light Ground | 1 | GRN/WHT | Tail Light Ground |

| 2 | BLK | Running Light Supply Ground | 2 | BLK | Running Light Supply Ground |

| 3 | BRN | Brake Light Supply Voltage | 3 | BRN | Brake Light Supply Voltage |

| Above the Rear Fender |

|

com1464

Loading image...

|

Version 1

|

C42 Turn Signal Flasher Connector Face View |

||

|

19225

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| 1 | BLU/BLK | Turn Signal Flasher Voltage |

| 2 | GRY/GRN | Turn Signal Lamp Control |

| 3 | BLK | Ground |

| Right Side of the Frame, Above the Power Pack Charger |

|

com1460

Loading image...

|

Version 1

|

C45 Hand Brake Switch Connector Face View |

|||

|

con0758

Loading image...

|

|||

|

Connector Part Information |

|

||

| Pin | Wire Color | Function | |

| 1 | BLU/BLK |

Hand Brake Switch Supply Voltage |

|

|

C45 Hand Brake Switch Connector Face View |

|||

|

con0758

Loading image...

|

|||

|

Connector Part Information |

|

||

| Pin | Wire Color | Function | |

| 2 | WHT/RED |

Hand Brake Switch Signal |

|

| Right Side of the Handlebar, Under the Master Cylinder |

|

com1465

Loading image...

|

Version 1

|

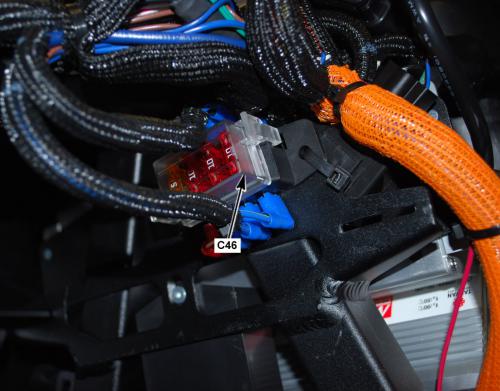

C46 Fuse Center Connector Bottom View |

||

|

con0757

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

|

1 |

BLU |

Fuse 4 Supply Voltage |

|

2 |

BLU |

Fuse 3 Supply Voltage |

|

3 |

BLU |

Fuse 2 Supply Voltage |

|

4 |

BLU |

Fuse 1 Supply Voltage |

|

7 |

BRN |

Voltage to Splice S299 |

|

8 |

BLU/BLK |

Voltage to Splice S27 • Horn • Turn Signal Flasher • Brake Switches |

|

9 |

BLU |

Accessory Power Port |

|

10 |

BLU/YEL |

Voltage to Splice S25 Headlight Switch |

| Under the Front Panels, In Front of the Power Pack |

|

com1456

Loading image...

|

Version 1

|

C47 Main Bike Board (MBB) Fuse Connector Face View |

|||

|

con0770

Loading image...

|

|||

|

Connector Part Information |

|

||

| Pin | Wire Color | Function | |

| 1 | ORN |

Low Voltage (+) Input |

|

| 2 | ORN/BRN |

Low Voltage (+) Output |

|

| Below the Front Power Pack, Across From the MBB, Inside the Harness Cover |

|

com1483

Loading image...

|

Version 1

|

C50 Quick Charge Connector Face View |

||

|

con0761

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

|

1 |

BLK |

Fused Battery Positive (+) |

|

2 |

BLK |

Battery Negative (-) |

|

P1-P2 |

— |

Not Used |

|

S1 |

WHT/BRN |

Charger Enable 1 |

|

S2 |

WHT/BLK |

Charger Enable 0 |

| Right Side of the Frame, Between the Brushless Motor Controller and the Motor |

|

com1462

Loading image...

|

Version 1

|

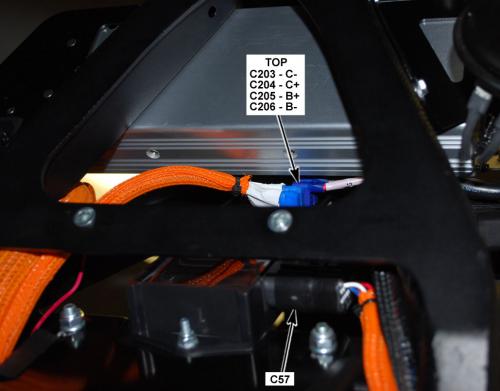

C57 Charger Control Unit (CCU) Connector Face View |

||

|

con0748

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

|

1-3 |

— |

Not Used |

|

4 |

BLK |

CAN Ground |

|

5 |

RED |

CAN 5 Volts |

|

6 |

BLU |

CAN 2 Low |

|

7 |

WHT |

CAN 2 High |

|

8-10 |

— |

Not Used |

|

11 |

ORN/GRN |

Charger Attached Signal |

|

12 |

WHT/BLK |

Charger Enable |

|

13 |

ORN/BLK |

Charger Ground |

|

14-18 |

— |

Not Used |

| Front of the Frame, Under the Power Pack Chargers |

|

com1466

Loading image...

|

Version 1

|

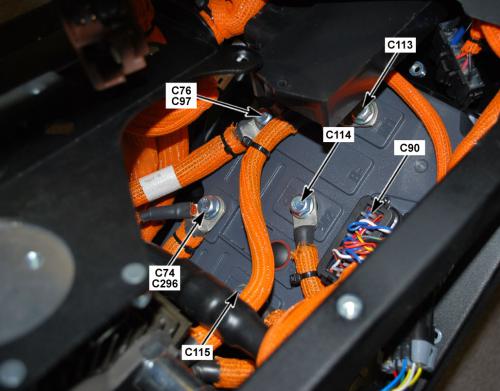

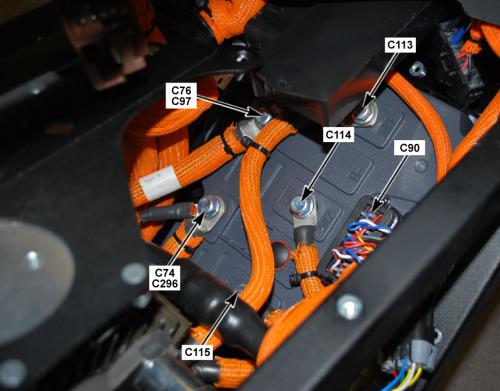

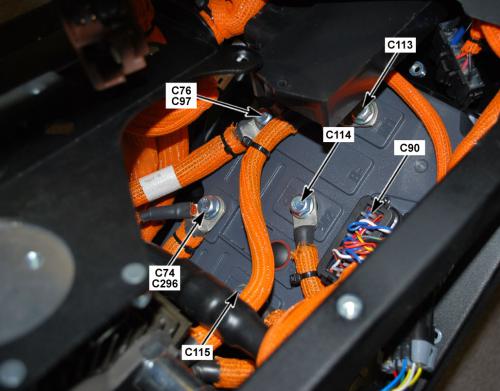

C74 Brushless Motor Controller Connector Face View |

||

|

con0051

Loading image...

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

|

— |

BLK (Orange Sleeve Over Cable) |

Positive (+) Voltage |

| Front of the Frame, Below the Front Power Pack |

|

com1467

Loading image...

|

Version 1

|

C76 Brushless Motor Controller Connector Face View |

||

|

con0051

Loading image...

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

|

— |

BLK (Orange Sleeve Over Cable) |

Negative (-) Ground |

| Front of the Frame, Below the Front Power Pack |

|

com1467

Loading image...

|

Version 1

|

C74 Brushless Motor Controller Connector Face View |

||

|

con0051

Loading image...

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

|

— |

BLK (Orange Sleeve Over Cable) |

Positive (+) Voltage |

| Front of the Frame, Below the Front Power Pack |

|

com1467

Loading image...

|

Version 1

|

C76 Brushless Motor Controller Connector Face View |

||

|

con0051

Loading image...

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

|

— |

BLK (Orange Sleeve Over Cable) |

Negative (-) Ground |

| Front of the Frame, Below the Front Power Pack |

|

com1467

Loading image...

|

Version 1

|

C79 Brushless Motor Controller Connector Face View |

||

|

con0050

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

|

— |

GRN/YEL |

Ground (C147 and C239) |

| Right Side of the Frame, Behind the Fuse Center |

|

com1469

Loading image...

|

Version 1

|

C90 Brushless Motor Controller Connector Face View |

||

|

19332

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| 1 | ORN/RED | Voltage From Key Switch |

| 2 | BLU | CAN Termination |

| 3-5 | — | Not Used |

| 6 | ORN/RED | Voltage From Key Switch |

| 7-14 | — | Not Used |

| 15 | BLK | Encoder Power Supply (–) |

| 16 | WHT | CAN High |

| 17 | — | Not Used |

| 18 | ORN/GRY | Digital Input 1 |

| 19 | ORN/BLU | Digital Input 3 |

| 20 | — | Not Used |

| 21 | BLU | Digital Input 8 |

| 22 | BRN | Throttle Sensor Signal |

| 23 | — | Not Used |

| 24 | BLU | CAN Low |

| 25 | — | Not Used |

| 26 | RED | Encoder Power Supply (+) |

| 27 | BLU | CAN Low |

| 28 | YEL/RED | CAN Power Supply (+) |

| 29-30 | — | Not Used |

| 31 | ORN/YEL | Digital Input 4 |

| 32 | ORN/VIO | Digital Input 7 |

| 33 | WHT | Temperature Sensor Input |

| 34 | BLU | Throttle Sensor Voltage |

| 35 | WHT | COSINE Input |

| Right Side of the Frame, Next to the Brushless Motor Controller |

|

com1462

Loading image...

|

Version 1

|

C97 Brushless Motor Controller Connector View |

||

|

con0051

Loading image...

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| — | BLK (Orange Sleeve Over Cable) | Fused Negative (-) |

| Front of the Frame, Below the Front Power Pack |

|

com1467

Loading image...

|

Version 1

|

C113 Brushless Motor Controller Face View |

||

|

con0051

Loading image...

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| — | BLK (Orange Sleeve Over Cable) | M1 Going to the Motor |

| Front of the Frame, Below the Front Power Pack |

|

com1467

Loading image...

|

Version 1

|

C114 Brushless Motor Connector Face View |

||

|

con0051

Loading image...

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| — | BLK (Orange Sleeve Over Cable) | Going to the Motor |

| Front of the Frame, Below the Front Power Pack |

|

com1467

Loading image...

|

Version 1

|

C115 Brushless Motor Connector Face View |

||

|

con0051

Loading image...

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| — | BLK (Orange Sleeve Over Cable) | Going to the Motor |

| Front of the Frame, Below the Front Power Pack |

|

com1467

Loading image...

|

Version 1

|

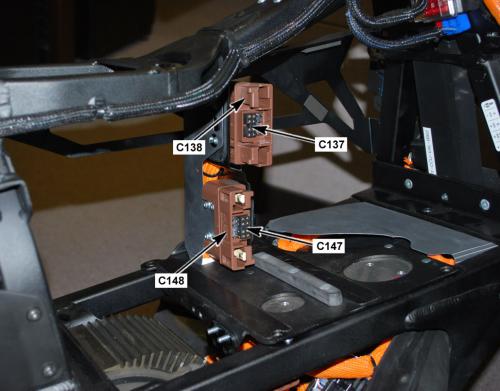

C137 Power Pack (Front) Signal Connector Face View |

||

|

con0766

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| P1 | ORN | Low Power B+ |

| P2 | RED | CAN 5 Volts |

| P3 | — | Not Used |

| P4 | YEL/GRY | 12 Volt Output |

| P5 | WHT | CAN High |

| P6 | — | Not Used |

| P7 | GRY/BRN | Node ID 1 |

| P8 | GRY/BRN | Ground |

| S1 | BRN | System ON Reference |

| S2 | BLK | CAN Ground |

| S3 | BRN/WHT | System ON |

| S4 | BLU | CAN Low |

| S5 | PNK | Loopback Output |

| S6 | GRN/YEL | Chassis Ground |

| S7 | PNK | Loopback Return |

| S8 | BLK/WHT | Throttle Enable |

| Center of the Frame, Between the Power Packs |

|

com1468

Loading image...

|

Version 1

|

C138 Front Power Pack Connector Face View |

||

|

con0767

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| 1 | BLK | Battery Positive (+) |

| 2 | BLK | Battery Positive (-) |

| Center of the Frame, Between the Power Packs |

|

com1468

Loading image...

|

Version 1

|

C147 Power Pack (Rear) Signal Connector Face View |

||

|

con0766

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| P1 | ORN ORN ORN |

Low Power B+ |

| P2 | RED RED |

CAN 5 Volts |

| P3 | — | Not Used |

| P4 | YEL/GRY YEL/GRY |

12 Volt Output |

| P5 | WHT WHT |

CAN High |

| P6 | GRY/BLK | Node ID 0 |

| P7 | GRY/BLK | Node ID 1 |

| P8 | GRY/BLK GRY/BLK |

Ground |

| S1 | BRN BRN |

System ON Reference |

| S2 | BLK BLK |

CAN Ground |

| S3 | BRN/WHT BRN/WHT |

System ON |

| S4 | BLU BLU |

CAN Low |

| S5 | PNK | Loopback Output |

| S6 | GRN/YEL GRN/YEL |

Chassis Ground to C79 |

| S7 | PNK | Loopback Input |

| S8 | BLK/WHT BLK/WHT |

Throttle Enable MBB and |

| Center of the Frame, Between the Power Packs |

|

com1468

Loading image...

|

Version 1

|

C148 Rear Power Pack Connector Face View |

||

|

con0767

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| 1 | BLK | Battery Positive (+) |

| 2 | BLK | Battery Positive (-) |

| Center of the Frame, Between the Power Packs |

|

com1468

Loading image...

|

Version 1

|

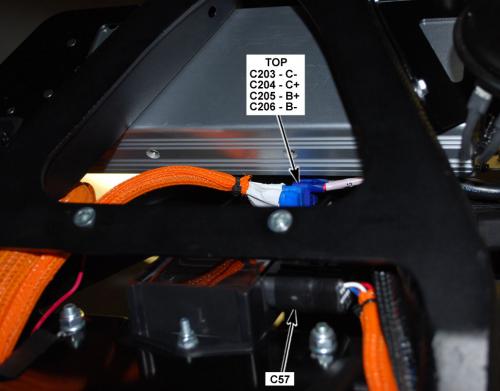

C203 Charger Control Unit (CCU) Connector Face View |

||

|

con0769

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| — | BLK | C- |

| Front of the Frame, Under the Power Pack Chargers |

|

com1466

|

Version 1

|

C204 Charger Control Unit (CCU) Connector Face View |

||

|

con0769

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| — | RED | C+ |

| Front of the Frame, Under the Power Pack Chargers |

|

com1466

|

Version 1

|

C205 Charger Control Unit (CCU) Connector Face View |

||

|

con0769

|

||

|

Connector Part Information |

|

|

|

Pin |

Wire Color |

Function |

| — | ORN | B+ |

| Front of the Frame, Under the Power Pack Chargers |

|

com1466

Loading image...

|

Version 1

|